Hit enter to search or ESC to close

Double Layer Ceiling Solution

Jump to

Double Layer Ceiling Solution

An alternative to our single layer solution, is our double layer solution.

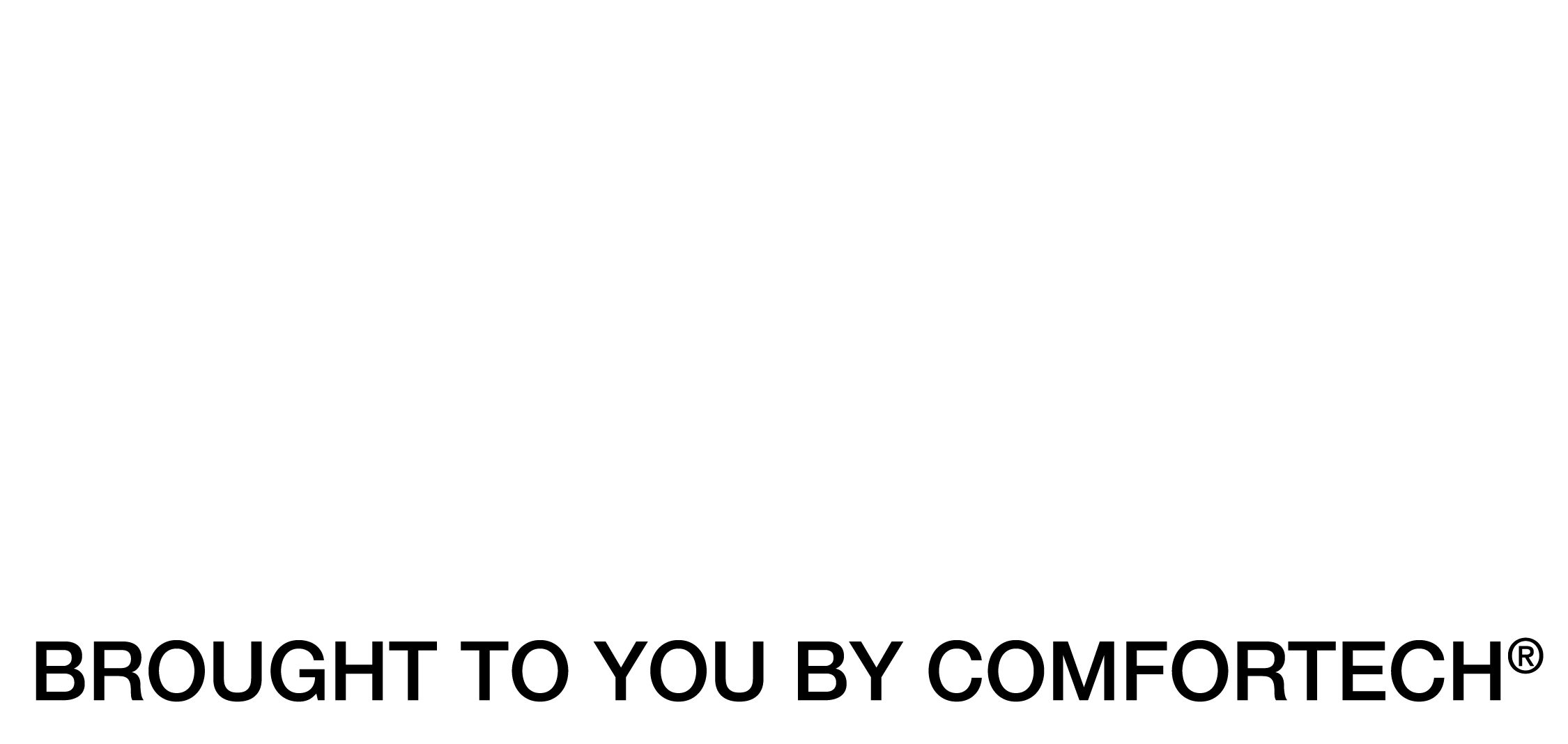

The Comfortech® double layer solution uses a:

- First layer of high-density Pink® Batts® insulation that is the combined height of the truss chord and the gap to the top of the ceiling batten. This layer is either 110mm for a 90mm truss chord, or 160mm for a 140mm truss chord

- Second layer of (460mm wide) Pink® Superbatts® insulation, installed at right angles to the first layer

- When the two layers are installed, the thermal bridge is completely closed, and the insulation performs as modelled

Double Layer Ceiling Installation

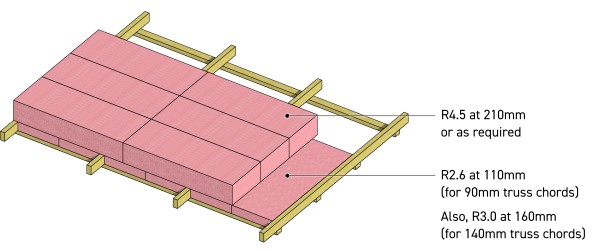

- With our two-layer solution, best practice is to install the top layer first, from below, across the truss chords

- The bottom layer is then pushed up under the top, to sit between the truss chords

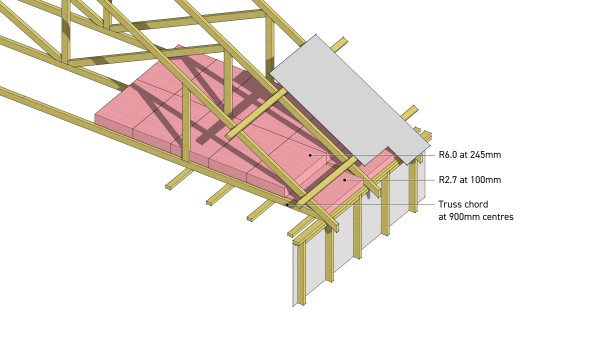

- At the roof perimeter, the Pink® Superbatts® are designed to be compressed under the insulation guard, with installation to the middle of the top plate required

- Using an insulation guard at the perimeter ensures contact between the insulation and roof underlay is avoided and a ventilation pathway is maintained

- For the two-layer solution, at the perimeter, the bottom layer is stopped short so the last 460mm is the higher R value top layer only; typically, R4.5 Pink® Superbatts®

- Pink® Superbatts® can be installed on a roof pitch of 18 degrees or above under perimeter compression over the last 460mm and still achieve the required perimeter R value, eliminating the need for a raised heel. When using Pink® Superbatts® R4.5, the roof pitch can go as low as 15 degrees whilst still achieving the required R value when under compression

Note: As an alternative to an insulation guard and edge compression, Comfortech® have developed a Pink® Batts® Perimeter solution that can be used under the H1 6th Edition.

Double Layer Ceiling Solution

Double Layer Ceiling Solution

Pink® Batts® Perimeter

With the reduction of the R value requirement for ceilings to a construction R value of R2.6 under the H1 6th Edition, we have released an R2.7 Pink® Batts® Perimeter product at 100mm thickness. Supplied at 560mm wide, our Pink® Batts® Perimeter is designed to cover over at least half of the top plate and extend up to 500mm into the ceiling space at the perimeter. Combined with the 460mm wide Pink® Superbatts® ceiling insulation solutions this ensures you can meet the requirements of the H1 6th Edition, while avoiding the need for a raise heel or an insulation guard.

Perimeter Ceiling Solution

Insulation Guard

As roof insulation increases in thickness to meet the new code, there is a greater differential in the surface temperature of the ceiling versus that of the top of the insulation. Therefore, warm air that escapes the warm interior through leakage and enters the roof cavity will likely condense; creating condensation; hence ensuring the adequate ventilation of the roof cavity is becoming mor critical under the new code.

Under the 5th Edition of H1 (effective in Nov. 2021), the last 500mm of the perimeter of the roof insulation could be reduced to R3.3; this allowed the insulation to carried out over the top plates of the wall, while reducing the barrier to air flow from the eave edges. With the 6th Edition of H1 update (released in Nov. 2025) the roof minimum R value has been further reduced to R2.6 and is applicable across the entire ceiling area. While this reduces the insulation thickness, there is however still a high risk, particularly in roofs with a pitch below 30 degrees of the insulation touching the underside of the roof underlay at the roof edge, preventing ventilation of the roof space, and creating a condensation and mould risk.

To address this, Comfortech have develop d a couple of practical solutions to address this challenge. The first is the installation of a roll panel vent over the trusses, under the underlay, to maintain this critical ventilation pathway. With an insulation guard specified and installed at the roof edge, edge compression of the Pink® Superbatts® ceiling insulation can then be utilised to avoid the need for a raised heel. The second solution, applicable when the design is utilizing 6th addition of H1, is the use of our new Pink® Batts® Perimeter solution.

Both solutions can offer a significant cost saving and avoid ‘height in relation to boundary’ issues, as well as simplifying the installation process and managing moisture within the roof space. For more information our Pink® Batts® Perimeter solution see below, to understand how edge compression can be utilized with Pink® Superbatts®, please visit our Edge Compression Calculator.

Download our Ceiling Product & Installation Guide